product

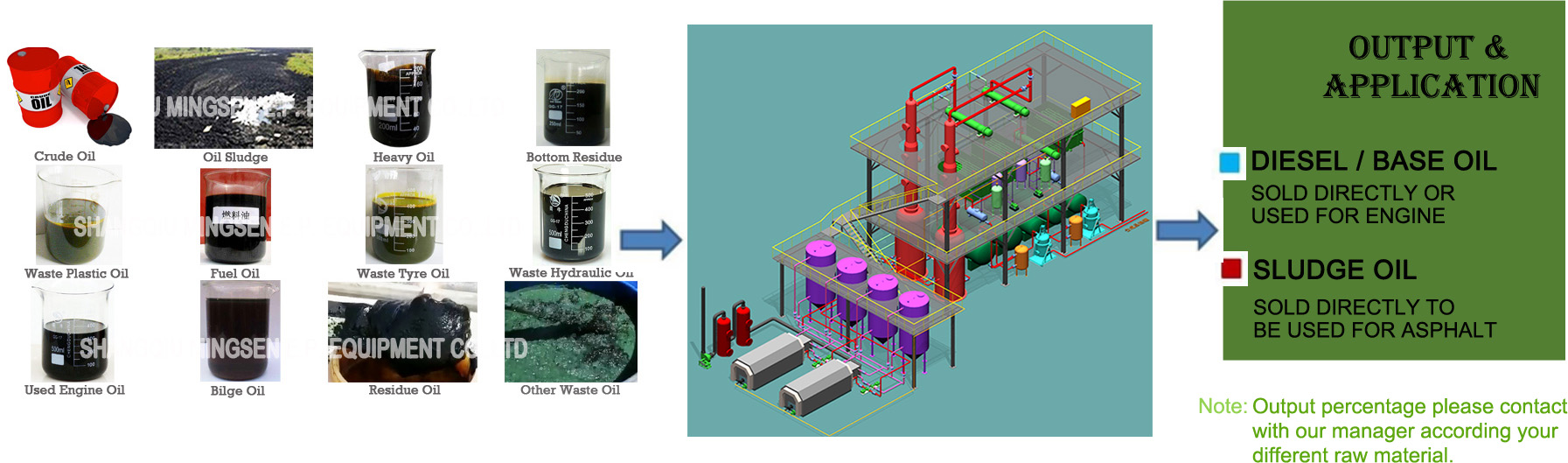

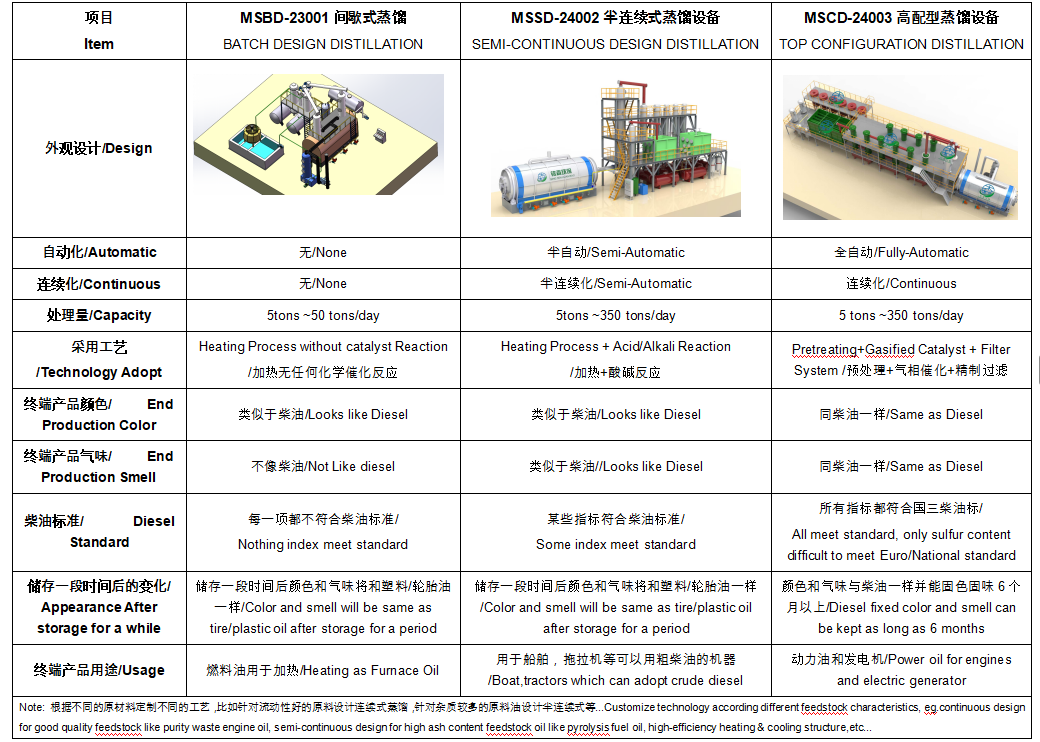

It is important to notice that motor oil does not wear out, it becomes contaminated after a cycle of use. A proper treatment technology allows to remove priority pollutants (polyaromatic hydrocarbons, toxic metals, chlorinated hydrocarbons) from used oil, so used motor oil can be re-refined to base lubricating oil, processed into fuel oil or applied as a stocks for petroleum-based production.

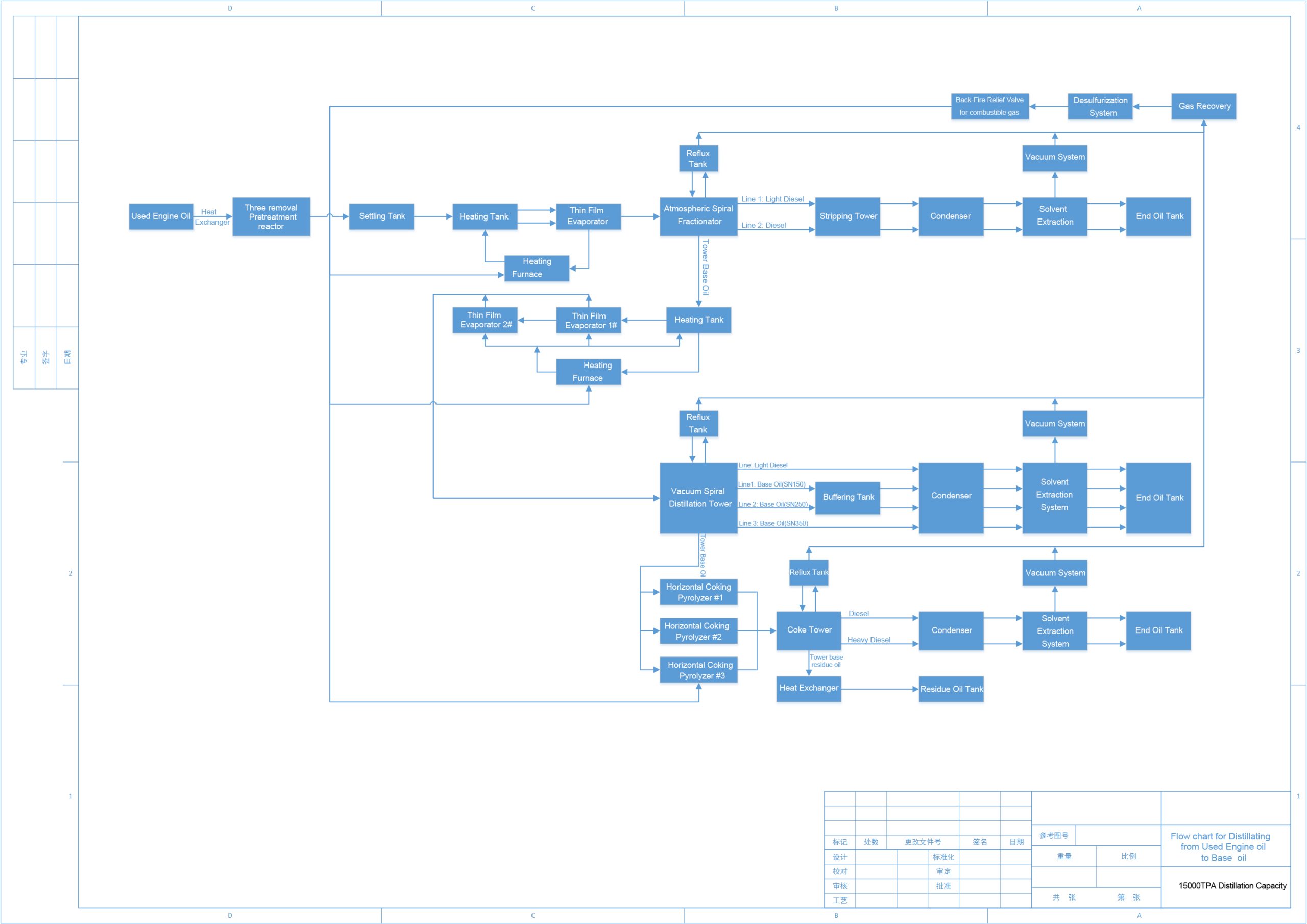

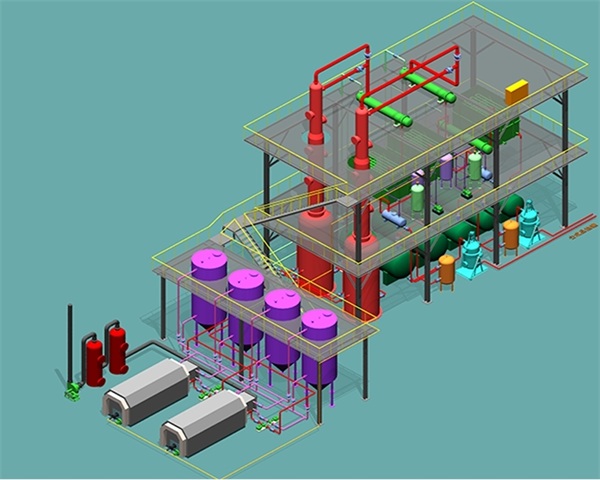

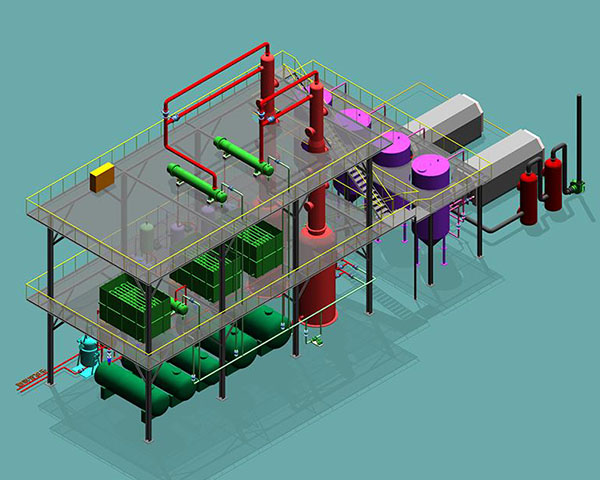

Pump raw oil into Pretreatment System through Automatic oil pump;

Remove Water,glue and other impurities to ensure end production quality;

Heating for Fractionating, Coal, Fuel Oil, Natural gas all can be used as heating fuel;

Second-time separate water and light naptha to ensure end production quality

Fractionating to get light diesel,diesel, heavy diesel and residue oil, Self-designed catalyst can be regenerated after, no second-time pollution.

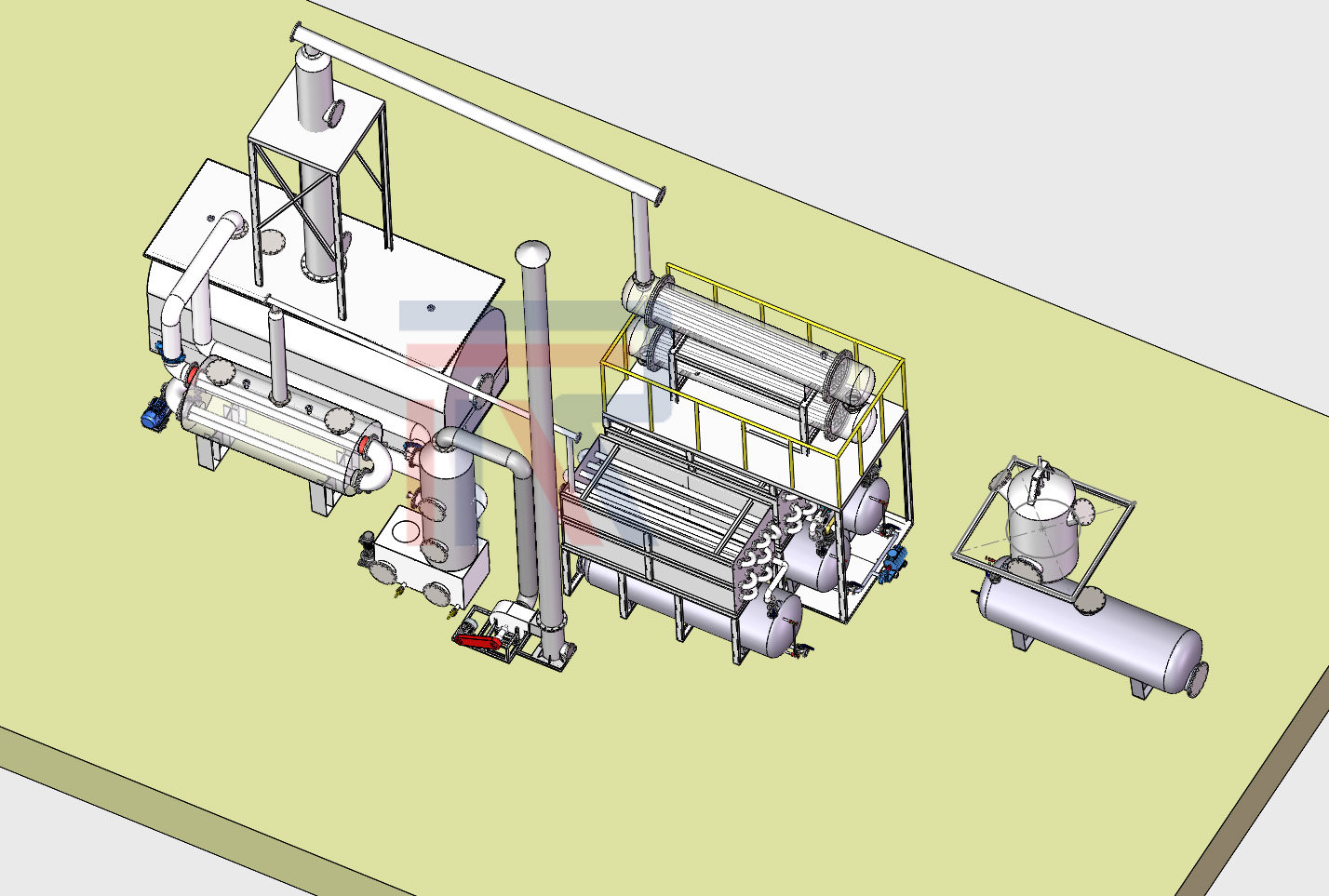

Quartz filter, Activated carbon filter and homemade adding filter, for fixing color and smell to be as long as 8 months.

Not only save energy and economical, but also avoid pollution.

Treated by professional industry purification system before emission,ensure meet national standard emission requirement;

Flexible operating can get 2 different production, get it according market demand.

Note:

1) Non-condensible gas is the gas which couldn’t be liquefaction under normal pressure;

2)Vacuum Delivery System also named as Vacuum Pneumatic Deliverying System.

|  |

| *Adopt atmospheric pressure prefractionating, and vacuum distillation, catalytic cracking distillation, solvent refining, solvent extraction and other new technologies; | *Adopt self-designed professional catalyst, filtration composite materials and other innovative technologies to ensure product quality; |

| *Catalyst can be regenerated, no second time pollution to environment, increase end production yield; | *End Production quality meet Euro standard, based on processing used engine oil or plastic oil. |

Waste engine oil/Crude Oil Distillation recycling machine Working Video:

Shangqiu Mingsen factory introduction:

Waste Used Engine Oil Recycling Distillation Plant Running in Thailand :

120TPD Waste Engine Oil Refinery Recycling to get Diesel SN150/SN250/SN350 BASE OIL Machine in China

Vietnam QAR 30TPD Waste Tire Pyrolysis Oil Recycling Distillation Plant Running Video

30TPD Used Engine Oil Recycling Distillation to Diesel Plant Running in Malaysia: